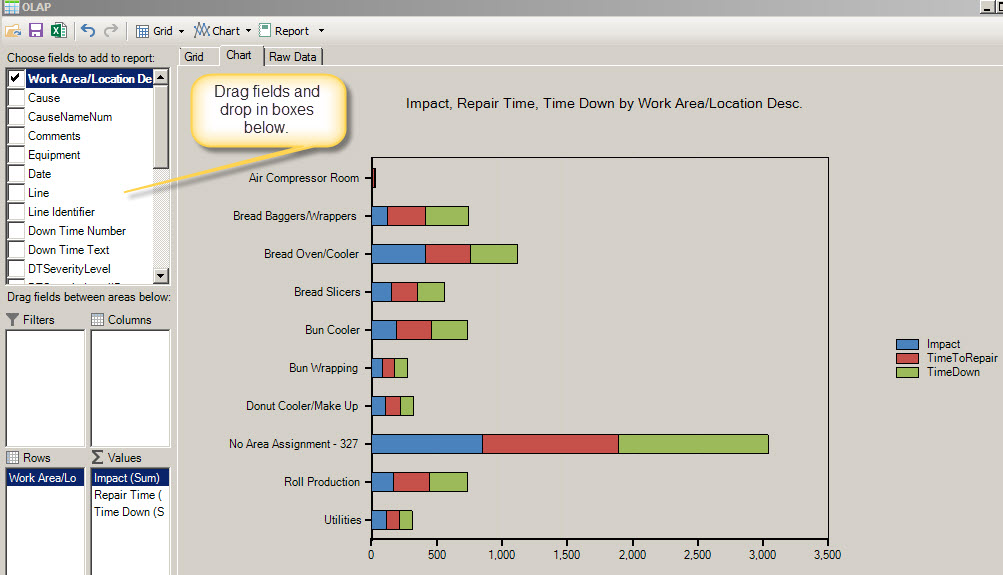

Tracking Equipment Downtime

Tracking Equipment Downtime is Worth the Effort Equipment downtime or unexpected equipment failures should be tracked in an effort to isolate and correct these destabilizing occurrences. This post focuses on using the report builder to generate powerful statistical analysis reports in seconds. The Dangers of Ignoring Downtime Data Unexpected equipment failures (downtime) lead to costly…

Read MorePreventive Maintenance Software Shortcuts

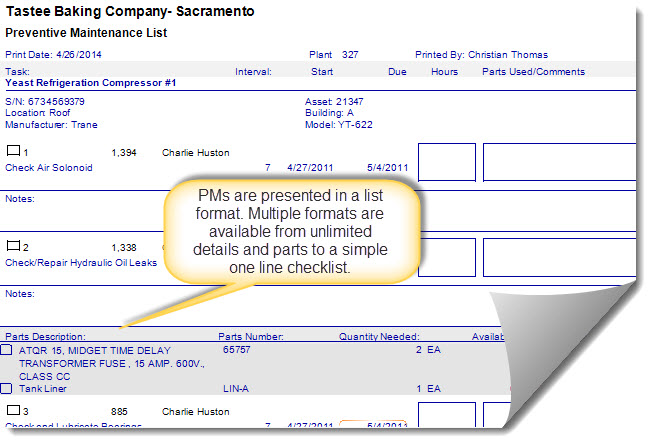

Preventive Maintenance Shortcuts Save Time MaintSmart preventive maintenance software handles PM either as a work order or from the special calendar-based PM screen. From this preventive maintenance screen each preventive maintenance item is a separate equipment, task, assigned person, start date and due date. By managing PMs this way preventive maintenance may be tracked more…

Read MorePreventative Maintenance Work Orders

Preventative Maintenance Tasks vs PM Work Orders This CMMS has two ways to create a preventative maintenance work order. The work order screen is the default way that all work is issued and managed for all CMMS software systems. This CMMS can work this same way. For the purposes of this discussion, we will consider…

Read MoreCMMS Purchasing Dashboard Upgrades for Version 5.0

Version 5.0’s Hot Sheet (CMMS dashboard) has a greatly enhanced purchasing section. The Hot Sheet identifies the users’ permission levels and provides the ability to drag and drop requisition approvals, requisitions and purchase orders.

Read More