Work Order Software

Training with Work Order Software

Work order software represents the basic functionality of any CMMS system. Typically Work orders represent one primary job but may be combined to create a project too. Required fields are Equipment and Task.

Prerequisite(s):

- Basic configuration and navigation.

- Equipment configuration.

- Task configuration.

- Personnel configuration.

This module covers several of the basics of work order and repair ticket creation, editing, printing, exporting and duplication. There is a great deal on information that is not covered, including many other shortcuts, tricks and methods for creating work orders. This CMMS software has seven (7) different way to create a work order.

Automatic Work Order Creation

Create work orders automatically or semi-automatically to respond to equipment breakdowns or to an equipment metric that is out of range. Additionally, create a work order from a similar work order by using a one-click duplication method. Best of all work order are created automatically based upon a schedule (example: Every Monday at 8:00AM) that you define. This schedule continues to generate work orders automatically, as expected. Furthermore, these work order are automatically emailed to the recipient of the job, or simply added to the work list.

In like fashion, work is triggered by meters (example: every 100 cycles or 100 hours) or other triggering events. Meters are defined by the maintenance manager and are any unit or value required. Accordingly, this adds great flexibility as well as automation to the work flow process. Use work order software for managing preventative maintenance, projects, repairs or any other type of equipment maintenance tasks.

Call us or email us for personalized instruction on any particular topic of interest not found in this series of instructional CMMS videos.

Phone: +1-541-404-0616

Work Orders Basic Data Entry

This video instructs on basic work order entry. Work orders may be created with as little as two fields or may be quite comprehensive with unlimited text detials and file attachments of any type.

Editing and Closing a Work Order

Learn how to edit and close a work order. Editing an existing data row is as simple as left-clicking the row containing the work order you wish to edit. After selection the data input boxes below the data grid become available for additions and changes.

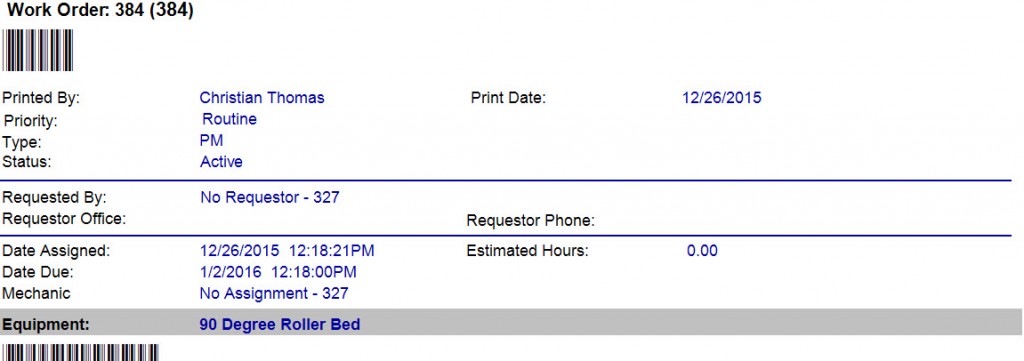

Printing and Exporting a Work Order

This sections describes how to export (print, save or email) a work order. Other reports associated with work orders are also discussed.

Linking Inventory to Work Orders

Learn how to link parts to a work order. Inventory parts may be linked at time of work order creation by editing the existing new work order or by linking the parts to a work order template then triggering the template to create a new work order.

Work Order Settings, Options and Shortcuts

Try some of the available time-saving settings and options from the CMMS software work order screen. This video describes several of these work order options.

Work Order Templates

There are numerous work order options and utilities available from the main work order screen. Additionally, there are seven more ways to create work orders, some are automatic, based upon schedule or event. Ultimately, work order templates are used to build an automated work order system. If you'd like a personal demonstration of how this is done contact us to schedule more training.